TRAINING

• All workers must be trained under careful and competent supervision before using any fall protection products.

• Manufacturer’s user instruction, warnings, caution and equipment

• Limitation should not just be reviewed and understood but also followed by the employees.

• Identify potential fall hazards.

• Determine which products to use in specific work environments.

• Demonstrate proper anchoring procedures.

• Inspect and maintain fall protection equipment.

• Demonstrate procedures and the proper wearing of fall protection equipment.

PLANNING FOR A RESCUE

• The rescue plan must be written in the hazard analysis.

• The goal is to rescue the employee as soon as possible and reduce the Hanging time.

• Plan to rescue a worker that is unconscious.

• Ensure all the rescue equipment is available in the near vicinity.

HORIZONTAL LIFELINE SYSTEM

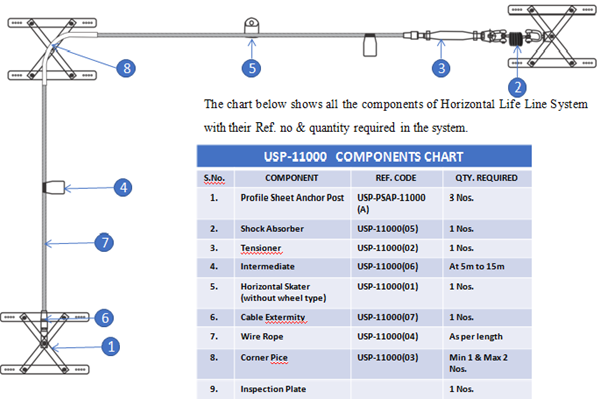

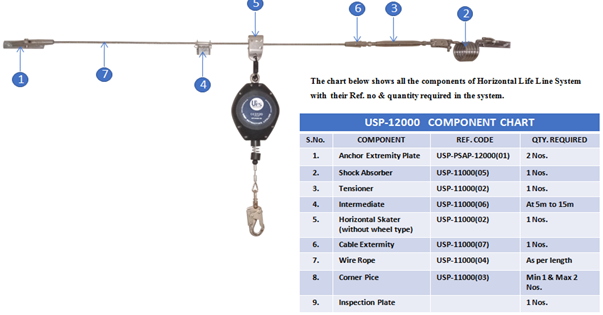

USP -11000 and USP-12000 provides permanent anchorage to a user who has to move constantly along the horizontal track .It comprises of wire rope, anchor extremity plate, shock absorber, tensioner, carriage body, intermediate & cable extremity which are made of Stainless Steel grade 316.The wire rope of 8 mm diameter (construction 7x19) runs all along the horizontal track which is installed at the ends using Anchor Extremity plates. The use of Shock Absorber reduces the impact of fall both on user as well as on the extremities.

The line also has Tensioner which regulates tensioning of the cable & both ends have a swage less termination. The Intermediate brackets hold the wire in position all along the length of the wire, and are installed at intervals of 5 to 15 mtrs. The main advantage of Intermediate bracket is that it can be oriented on all directions.

The line also has Carriage Body which connects the user to the line with the help of a lanyard/ retractable block, and moves smoothly without interruption along the entire length of the horizontal line and also through the intermediate brackets, ensuring 100% anchorage of the user at all times.

USP-11000 (Over The Roof) HORIZONTAL LIFELINE SYSTEM

The system has an Inspection Name Plate which is installed on the first rung of the ladder for identification, traceability, maintenance of inspection records. Two stainless steel cable ties are used to fasten the System name plate to the structure. At time of installation, the relevant details are punched on the plate by a number punch. The revalidation dates are punched each year on the plates after inspection and revalidation .The system is versatile and can be installed on walls, Floors, Ceilings as well as on Roof tops, using the same components by just altering the orientation of the Intermediate Brackets.

USP-12000 (Over The Head) HORIZONTAL LIFELINE SYSTEM

USP-1000 VERTICAL LIFELINE

ALL PROTECTION REFRESHER ORIENTAION

“You weren’t listening. I said, ‘Don’t fall.”

USP-1000 VERTICAL LIFELINE

Vertical Lifeline Systems can be permanently installed to a ladder or other vertical structure that requires frequent access. It provides a safe, functional and practical means of access.

Vertical Lifeline Systems are suitable for use in a number of applications including.

• Ladder access

• Lattice construction towers and monopoles

• Wind turbine access

• Lighting column access

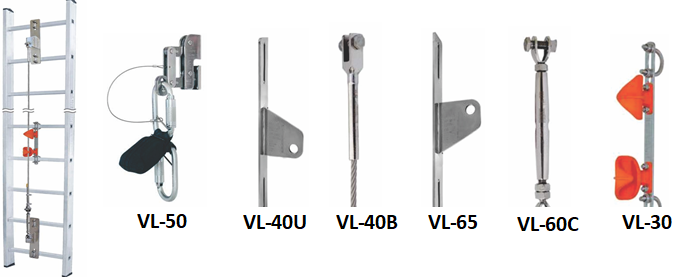

USP-1000 VERTICAL LIFELINE COMPONENTS

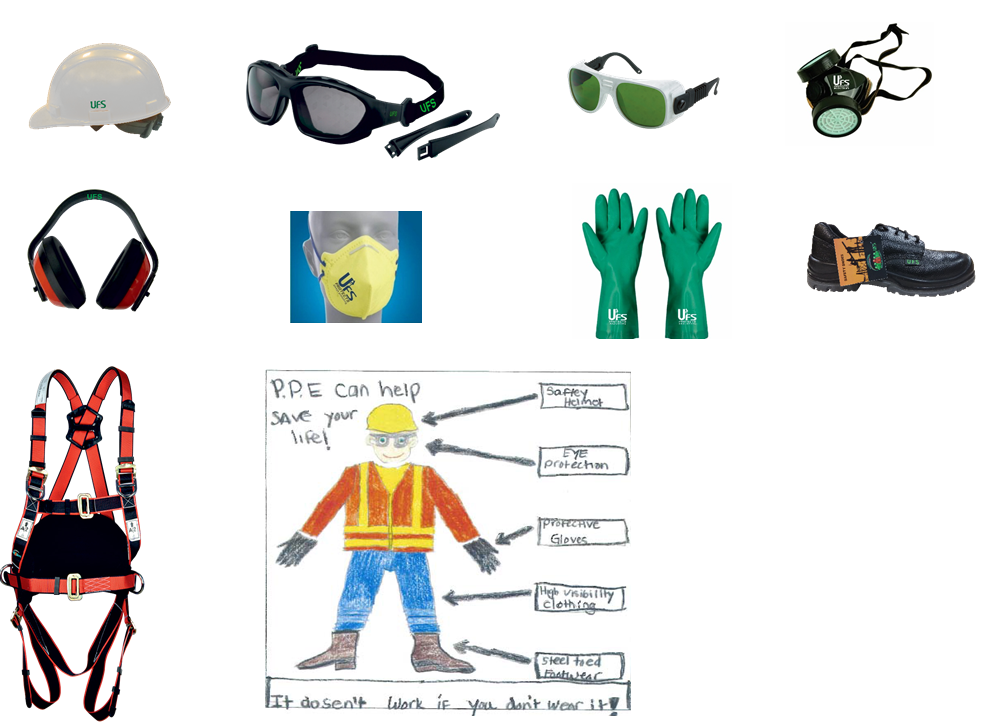

RECOMMENDED PPE